How Do Plastic Injection Molding Machines Work?

December 15, 2010

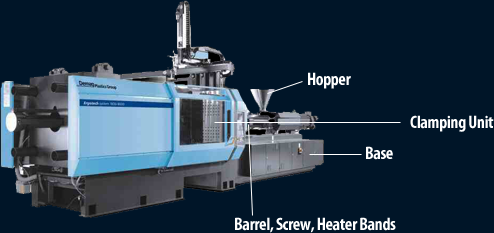

There are horizontal injection molding machines and vertical injection molding machines. While horizontal injection molding machines are very popular, vertical injection molding machines are very versatile and can save valuable floor space. A horizontal injection molding machine is pictured to the right.

There are horizontal injection molding machines and vertical injection molding machines. While horizontal injection molding machines are very popular, vertical injection molding machines are very versatile and can save valuable floor space. A horizontal injection molding machine is pictured to the right.

Hopper

This serves as a funnel into the barrel. The hopper is where the plastics resin is placed for injection. Plastic resin can be compromised of flakes, shavings or pellets. The plastic resin can be fed manually, automatically or via vacuum.

Barrel, Injection Molding Screw, Heater Bands

The injection molding screw has dual purpose in the function of an injection molding machine as it rotates, melts plastic and injects it into the mold. There are a series of bands (heater bands) around the barrel. The purpose of these bands is to keep the barrel at an even temperature throughout the injection moulding process.

The injection molding screw has dual purpose in the function of an injection molding machine as it rotates, melts plastic and injects it into the mold. There are a series of bands (heater bands) around the barrel. The purpose of these bands is to keep the barrel at an even temperature throughout the injection moulding process.

Clamping Unit & Platens

There are 2 platens in every injection molding machine. Platens are made of steel and each one holds half of the mold. The machine clamp opens and closes the mold.

Some popular types of clamps are hydraulic, toggle or 2-platen .